Project Description

The main component of ETHACURE-300 curing agent is dimethylthiotoluenediamine (DMTDA). It is a trademark registered by Albemarle. In order to better understand and recognize this curing agent mainly containing DMTDA. We use Albemarle-E300 to explain because its information is more detailed.

CAS No.: 106264-79-3

EINECS Number: 403-240-8

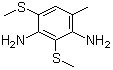

Molecular Formula: C9H14N2S2

Molecular Weight: 214.36

Properties

Molecular weight: 214.

Boiling point: 353℃.

Density (at 20℃): 1.21 g/cm3.

Freezing point: -9℃.

Flash point (TCC): 163.4℃.

Viscosity (at 20℃): 280 Cps.

Ethanol: miscible.

Toluene: miscible.

Water: 1.0.

Isocyanate equivalent: 107.

Epoxy resin Equivalent: 53.5.

Click here to get the Albemarle MSDS.

Specifications

Appearance (at room temperature): light yellow to amber clear liquid.

DMTDA active ingredients: 95-97%.

MMTDA active ingredients: 2-3%.

TDA content: less than 1.0%.

Amine value: 536 mgKOH/g.

Moisture: less than 0.1.

Applications

Albemarle E300 is an environmentally friendly and low-toxic liquid diamine chain extender.

It is mainly used in polyurethane elastomers, RIM (Reaction Injection Molding), SPUA (Spray Polyurea Elastomer) and adhesives.

It can also be used as an epoxy curing agent. Albemarle E300 is now widely used in polyurethane rubber rollers, medicine, stamping, and molding, etc.

The ETHACURE 300 curative can also be used as an epoxy curing agent. Has been widely used in polyurethane rubber roller, medicine, stamping, and other aspects.

In addition, it has a wide range of applications in the automotive, construction, coal mining, metal mining, textile, paper, and printing industries.

Albemarle E300 curing speed is much slower than DETDA. It can be mixed with DETDA in different proportions to adjust the curing speed to meet different needs.

Albemarle E300 processing performance and its use performance.

Albemarle E300 is a low viscosity liquid at room temperature. It has good liquidity. Therefore, it provides flexibility for the temperature at which the prepolymer is blended with the curing agent. According to this situation, it also has the following advantages.

- Good compatibility with other components.

- When the NCO% content in the prepolymer is low, the curing time it requires is shorter than that of MOCA. This is more advantageous for the operator.

- When the NCO% content in the prepolymer is high, it takes a long time to cure because of its high reactivity. This is particularly advantageous for the operator.

- Under the same NCO% content, the equivalent value of DMDDA is smaller, so its dosage is less than that of MOCA.

In addition, it has a wide range of applications in the automotive, construction, coal mining, metal mining, textile, paper, and printing industries.

DMTDA’s curing speed is much slower than DETDA. It can be mixed with DETDA in different proportions to adjust the curing speed to meet different needs.

Packing and Storage:

200 kg iron drum, sealed with nitrogen. If you can’t use one iron drum at a time, refill it with nitrogen and store it in a sealed container.

Avoid outdoor exposure or prolonged exposure to high temperatures. Albemarle E300 is best to store this product above 0℃. We can guarantee long-term quality unchanged.

When the product is stored and exposed to air, the product gradually darkens. This is normal.